solar high power led lantern

by:Taiyi Electronic

2020-04-03

Solar Lanterns already exist ,(

Mpowrd Luci found here, for example)

And the price is not too expensive, but most of them are not very bright.

I have one, I like it, but I always use my propane lantern when I am camping.

I would like something that is comparable to propane lights in brightness, or at least my friend and I can sit and play cards without any trouble.

So, I started building one myself.

In addition to the higher power than Luci, I would like it to have a similar price, so I have to salvage as many parts as possible for this project.

I was able to get the led I needed from my burnt home LED bulb and get 18650 lithium ion batteries from my old laptop battery.

On top of that, I was lucky enough to find a solar panel on a solar safety light that didn\'t work in the bin.

Compared with Luci\'s 80 lumens, the final result is about 400 lumens.

It\'s not as bright as a propane lantern, but it\'s perfect for playing cards.

The battery life is shorter than luci, but about 3.

5 hours, which is enough for a satisfying card game, I spent about $10.

All in all, I am happy with the end result, but I will change/possibly change something in the future (

Mainly enclosure).

To complete this project, you need to have a basic understanding of the electronics, how to use a multimeter, and some welding skills.

In this Instructure, I will use the exact section I use to illustrate in detail step by step in the photo.

However, there is also a lot of room for improvisation in this project.

If you like this note, please vote for it!

I would also love to see a modified version of this in the comments!

Here is the parts list :-A \"burnt out\" (

I don\'t think it has to be burned)LED lightbulb.

I\'m using a 60 W Phillips slim style.

You can find it here if you want to use the exact part I use, but most LED bulbs may work.

I quoted \"burn out\" in the citation as there are almost always a lot of very good high power LEDs in the burnt LED bulbs!

Let them leave the landfill! -A pair (or more)

18650 lithium battery.

You can easily remove them from your old laptop battery (

There are instructions on how to do this)

Or you can buy it on ebay for free. -

18650 battery stands like this, but note that on the battery stand I bought, the connected wires don\'t actually work.

I had to weld on the new one. -

2s 18650 charging circuit/Protection Board.

I used this. -

Buck converter.

I used one of them. -

12v solar panels.

You\'re a little alone with this.

You may be able to float the charger with a car like this, but it may be a bit big.

I Rescued My from the old solar safety light. -A spdt switch.

You may find one on ebay and I have one. -

A shell of some type.

I used a quart Talenti ice cream container.

It\'s okay, but I know you can find something better! -

Waste wood, solder, glue, hot glue, wires, etc.

It\'s almost something a manufacturer should have at any time.

Tools: miniature flat head screwdriver for adjusting the buck converter and paper angle grinder or dremelmultimeteris\'s soldering iron hot glue gun! .

You can skip this step if you really want it, but I think it\'s fun!

When I started this project, I had some knowledge of the circuits, but I didn\'t know much about the LEDs, and I didn\'t know how they worked, but through a lot of research, here is the information I have collected:

Oh, for any LED \"veteran\", please correct me in the comments if there is any error. )1.

LED has something called \"forward voltage.

This is an \"ideal\" voltage that an LED will take.

It is usually between 2 and 8 volts, but depending on the type of LED you are using.

In addition, due to atmospheric conditions such as temperature, the voltage between the two LEDs of the same type may vary slightly. 2.

Under the ideal voltage of the LED, the LED will let the ideal current pass through it.

For example, a 1-watt LED with a forward voltage of 3.

2v will get around.

313 amps or 313 mA through it.

This is calculated by the power equation: Power = current * voltage.

In this case, the power is 1 W and the voltage is 3 W.

The current must be 2 v. 313A. 3.

The voltage changes around the LED forward voltage are small, resulting in a large change in current.

This is dangerous for LEDs because they can easily burn out by too much current.

This is combined with the fact that each forward voltage of the LED is different, and it can lead to some frustrating time when designing the LED array.

Most people solve this problem in two ways:. )

Use resistance in series with each LED ball. )

Use something called a \"constant current drive\" and connect the LED in series (

This is the option for most high power arrays to use, because the resistance burns down when a large amount of current passes through the resistor. )

This type of regulator does not let more than the set amount of current pass through it, so the LEDs that apply a higher voltage than the forward voltage do not generate additional current.

Since I am a rebel, I will do NIETHER in this directive! (

Or just lazy)

When the LED bulb \"burns out\", it is usually caused by a bad component on the PCB.

If it is a burnt out LED, there is usually only one, which means that the rest of the LED is good and acceptable!

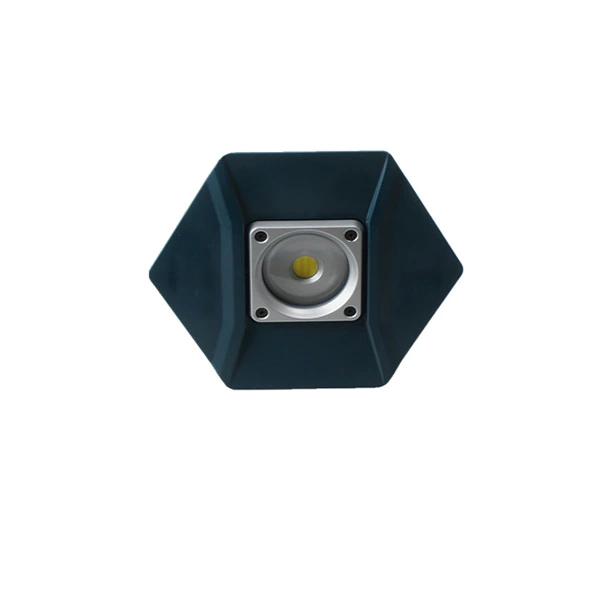

We need to take apart the LED bulb.

This requires some trial and error, but for my specific bulb I tore the bottom with pliers and pried the case with a screwdriver.

In the LED bulb, the LED has been conveniently packaged and welded to the board.

However, they are in series, which is good in some cases, but not in our case.

This is because when led is connected in series, their forward voltage increases.

In the case of the bulb I use, there are 30 LEDs.

If the forward voltage of each LED is 3 V, then it will take about 96V for the array to light up.

At the same time, our poor 18650 series battery can only supply about 7. 2V. (

You might do this using the boost converter, but I digress. . . )

Long story short, we need to cut traces between each LED in series and wire them in parallel.

Using dremel (

Or angle grinder)

Completely cut the marks and sandpaper to expose the welding marks.

When you cut, be careful not to break the LEDs.

After the trace is cut and polished, Weld one wire to each positive trace of the LEDs and the other to each negative trace.

If you are using my bulb, you can follow in the picture.

After completion, use a multimeter to ensure that there is no short circuit between the two parallel buses (

Unlimited resistance).

Note: technically, for each LED, you should not route the LED in parallel without resistance.

This is especially true when you use a constant current regulator.

This is related to what was mentioned in the previous step.

Basically, because the LED with the lowest forward voltage will drain all the current and drain itself, then the current used by the burnt out LED will be distributed to the LED at the next lowest forward voltage, this will cause the LED to burn out and so on.

However, because we are using a voltage-regulated power supply, not a current-regulated power supply, if one LED burns out, the voltage of each other LED will be exactly the same, so the current will be exactly the same.

So the worst thing that could happen is that you run out of one of the LEDs in the array (

I can remind you that it\'s free anyway).

For this step you can follow in my photo or just take a look at the schematic in the intro.

Basically, you need to weld the negative pole of one battery seat with the positive pole of the other battery seat on the spot on the board marked \"BM.

After that, just weld the other two wires on the battery stand to B-

There are B points on the blackboard.

You also need to weld connectors for input and output voltage wires.

Note: Make sure to do so without installing the battery stand!

The first time I welded these boards, I accidentally released some magical smoke because the exposed wires came into contact with the wrong place!

After welding the battery holder, you can put the battery and test the output voltage of the circuit board using a multimeter. (

If the battery is charged, it should be around 8 v. )

Note: on the particular board I use for this, you may have to \"activate\" it by briefly connecting the charging cable to some DC voltage source (

AC adapter like 9v or 12 v)

When installing the battery.

The rated power of my specific bulb is 10. 5 watts.

However, I only use half of the LEDs, which means I should use only half of the power consumption (around 5 watts).

This information is essential for finding forward voltage.

This means that the voltage used to power my LEDs times the current used by the LEDs should never be greater than 5!

To do this, you need to weld the wires to the four terminals of the buck converter.

Charge the battery and install it in the bracket, connect the positive and negative outputs of the charging board to the positive and negative inputs on the step-down converter. (

Don\'t weld them together, it\'s just for testing. )

Measure the voltage output of the buck converter with a multimeter, use a flat head screwdriver, adjust the potentiometer on the buck converter until the output voltage is around 2. 5V.

This will be our starting point.

Now connect the parallel array of LEDs to the output of the step-down converter.

Turn the potentiometer until the led is on.

Please pay attention to the voltage in which this happens.

At this point, the multimeter is connected in series with the LEDs to measure the current they absorb.

Now multiply the voltage by the current.

If the product has a lot under the rated power consumption of the led, you can try to turn the voltage up a bit and then re-measuring.

Do this until you have the brightness you want (

But don\'t be greedy or you will burn out LEDs).

I found that the forward voltage of the LEDs I use is about 3. 1V.

Now that you have adjusted the buck converter correctly, Weld its output to the LED array (

Check the polarity of course). Next, solder (one of)

Ground wire (s)

From the charging board to the intermediate terminal of the spdt switch.

At this point, weld the negative input of the buck converter to an external terminal of the switch and weld the negative terminal of the solar panel to another external terminal on the switch.

Finally, weld the positive pole of the solar panel to the positive input of the charging board and weld the positive output of the charging board to the positive input of the buck converter.

If you are confused, you can refer to my introduction schematic.

Your circuit is done!

Now, just find a way to wrap it well and spread out the light emitted by the LEDs.

I used a Talenti Gelato container that I polished outside to make it translucent.

However, it is a bit heavy and I am not completely satisfied with it.

Let me know what you came up!

Thanks for reading!

Don\'t forget to vote for my guide if you like it!

Mpowrd Luci found here, for example)

And the price is not too expensive, but most of them are not very bright.

I have one, I like it, but I always use my propane lantern when I am camping.

I would like something that is comparable to propane lights in brightness, or at least my friend and I can sit and play cards without any trouble.

So, I started building one myself.

In addition to the higher power than Luci, I would like it to have a similar price, so I have to salvage as many parts as possible for this project.

I was able to get the led I needed from my burnt home LED bulb and get 18650 lithium ion batteries from my old laptop battery.

On top of that, I was lucky enough to find a solar panel on a solar safety light that didn\'t work in the bin.

Compared with Luci\'s 80 lumens, the final result is about 400 lumens.

It\'s not as bright as a propane lantern, but it\'s perfect for playing cards.

The battery life is shorter than luci, but about 3.

5 hours, which is enough for a satisfying card game, I spent about $10.

All in all, I am happy with the end result, but I will change/possibly change something in the future (

Mainly enclosure).

To complete this project, you need to have a basic understanding of the electronics, how to use a multimeter, and some welding skills.

In this Instructure, I will use the exact section I use to illustrate in detail step by step in the photo.

However, there is also a lot of room for improvisation in this project.

If you like this note, please vote for it!

I would also love to see a modified version of this in the comments!

Here is the parts list :-A \"burnt out\" (

I don\'t think it has to be burned)LED lightbulb.

I\'m using a 60 W Phillips slim style.

You can find it here if you want to use the exact part I use, but most LED bulbs may work.

I quoted \"burn out\" in the citation as there are almost always a lot of very good high power LEDs in the burnt LED bulbs!

Let them leave the landfill! -A pair (or more)

18650 lithium battery.

You can easily remove them from your old laptop battery (

There are instructions on how to do this)

Or you can buy it on ebay for free. -

18650 battery stands like this, but note that on the battery stand I bought, the connected wires don\'t actually work.

I had to weld on the new one. -

2s 18650 charging circuit/Protection Board.

I used this. -

Buck converter.

I used one of them. -

12v solar panels.

You\'re a little alone with this.

You may be able to float the charger with a car like this, but it may be a bit big.

I Rescued My from the old solar safety light. -A spdt switch.

You may find one on ebay and I have one. -

A shell of some type.

I used a quart Talenti ice cream container.

It\'s okay, but I know you can find something better! -

Waste wood, solder, glue, hot glue, wires, etc.

It\'s almost something a manufacturer should have at any time.

Tools: miniature flat head screwdriver for adjusting the buck converter and paper angle grinder or dremelmultimeteris\'s soldering iron hot glue gun! .

You can skip this step if you really want it, but I think it\'s fun!

When I started this project, I had some knowledge of the circuits, but I didn\'t know much about the LEDs, and I didn\'t know how they worked, but through a lot of research, here is the information I have collected:

Oh, for any LED \"veteran\", please correct me in the comments if there is any error. )1.

LED has something called \"forward voltage.

This is an \"ideal\" voltage that an LED will take.

It is usually between 2 and 8 volts, but depending on the type of LED you are using.

In addition, due to atmospheric conditions such as temperature, the voltage between the two LEDs of the same type may vary slightly. 2.

Under the ideal voltage of the LED, the LED will let the ideal current pass through it.

For example, a 1-watt LED with a forward voltage of 3.

2v will get around.

313 amps or 313 mA through it.

This is calculated by the power equation: Power = current * voltage.

In this case, the power is 1 W and the voltage is 3 W.

The current must be 2 v. 313A. 3.

The voltage changes around the LED forward voltage are small, resulting in a large change in current.

This is dangerous for LEDs because they can easily burn out by too much current.

This is combined with the fact that each forward voltage of the LED is different, and it can lead to some frustrating time when designing the LED array.

Most people solve this problem in two ways:. )

Use resistance in series with each LED ball. )

Use something called a \"constant current drive\" and connect the LED in series (

This is the option for most high power arrays to use, because the resistance burns down when a large amount of current passes through the resistor. )

This type of regulator does not let more than the set amount of current pass through it, so the LEDs that apply a higher voltage than the forward voltage do not generate additional current.

Since I am a rebel, I will do NIETHER in this directive! (

Or just lazy)

When the LED bulb \"burns out\", it is usually caused by a bad component on the PCB.

If it is a burnt out LED, there is usually only one, which means that the rest of the LED is good and acceptable!

We need to take apart the LED bulb.

This requires some trial and error, but for my specific bulb I tore the bottom with pliers and pried the case with a screwdriver.

In the LED bulb, the LED has been conveniently packaged and welded to the board.

However, they are in series, which is good in some cases, but not in our case.

This is because when led is connected in series, their forward voltage increases.

In the case of the bulb I use, there are 30 LEDs.

If the forward voltage of each LED is 3 V, then it will take about 96V for the array to light up.

At the same time, our poor 18650 series battery can only supply about 7. 2V. (

You might do this using the boost converter, but I digress. . . )

Long story short, we need to cut traces between each LED in series and wire them in parallel.

Using dremel (

Or angle grinder)

Completely cut the marks and sandpaper to expose the welding marks.

When you cut, be careful not to break the LEDs.

After the trace is cut and polished, Weld one wire to each positive trace of the LEDs and the other to each negative trace.

If you are using my bulb, you can follow in the picture.

After completion, use a multimeter to ensure that there is no short circuit between the two parallel buses (

Unlimited resistance).

Note: technically, for each LED, you should not route the LED in parallel without resistance.

This is especially true when you use a constant current regulator.

This is related to what was mentioned in the previous step.

Basically, because the LED with the lowest forward voltage will drain all the current and drain itself, then the current used by the burnt out LED will be distributed to the LED at the next lowest forward voltage, this will cause the LED to burn out and so on.

However, because we are using a voltage-regulated power supply, not a current-regulated power supply, if one LED burns out, the voltage of each other LED will be exactly the same, so the current will be exactly the same.

So the worst thing that could happen is that you run out of one of the LEDs in the array (

I can remind you that it\'s free anyway).

For this step you can follow in my photo or just take a look at the schematic in the intro.

Basically, you need to weld the negative pole of one battery seat with the positive pole of the other battery seat on the spot on the board marked \"BM.

After that, just weld the other two wires on the battery stand to B-

There are B points on the blackboard.

You also need to weld connectors for input and output voltage wires.

Note: Make sure to do so without installing the battery stand!

The first time I welded these boards, I accidentally released some magical smoke because the exposed wires came into contact with the wrong place!

After welding the battery holder, you can put the battery and test the output voltage of the circuit board using a multimeter. (

If the battery is charged, it should be around 8 v. )

Note: on the particular board I use for this, you may have to \"activate\" it by briefly connecting the charging cable to some DC voltage source (

AC adapter like 9v or 12 v)

When installing the battery.

The rated power of my specific bulb is 10. 5 watts.

However, I only use half of the LEDs, which means I should use only half of the power consumption (around 5 watts).

This information is essential for finding forward voltage.

This means that the voltage used to power my LEDs times the current used by the LEDs should never be greater than 5!

To do this, you need to weld the wires to the four terminals of the buck converter.

Charge the battery and install it in the bracket, connect the positive and negative outputs of the charging board to the positive and negative inputs on the step-down converter. (

Don\'t weld them together, it\'s just for testing. )

Measure the voltage output of the buck converter with a multimeter, use a flat head screwdriver, adjust the potentiometer on the buck converter until the output voltage is around 2. 5V.

This will be our starting point.

Now connect the parallel array of LEDs to the output of the step-down converter.

Turn the potentiometer until the led is on.

Please pay attention to the voltage in which this happens.

At this point, the multimeter is connected in series with the LEDs to measure the current they absorb.

Now multiply the voltage by the current.

If the product has a lot under the rated power consumption of the led, you can try to turn the voltage up a bit and then re-measuring.

Do this until you have the brightness you want (

But don\'t be greedy or you will burn out LEDs).

I found that the forward voltage of the LEDs I use is about 3. 1V.

Now that you have adjusted the buck converter correctly, Weld its output to the LED array (

Check the polarity of course). Next, solder (one of)

Ground wire (s)

From the charging board to the intermediate terminal of the spdt switch.

At this point, weld the negative input of the buck converter to an external terminal of the switch and weld the negative terminal of the solar panel to another external terminal on the switch.

Finally, weld the positive pole of the solar panel to the positive input of the charging board and weld the positive output of the charging board to the positive input of the buck converter.

If you are confused, you can refer to my introduction schematic.

Your circuit is done!

Now, just find a way to wrap it well and spread out the light emitted by the LEDs.

I used a Talenti Gelato container that I polished outside to make it translucent.

However, it is a bit heavy and I am not completely satisfied with it.

Let me know what you came up!

Thanks for reading!

Don\'t forget to vote for my guide if you like it!