700 cd led bike light - from osram spotlight

by:Taiyi Electronic

2020-02-23

I have been following the development of LED replacement household bulbs.

In my opinion, a good home headheld spotlight will be a very cheap front light for a bike.

The perfect Osram headheld spotlight-

In my local DIY shop

So I went.

I am very satisfied with the results.

I found out that I spent about £ 20 doing a bike light and retail £ 200 from the bike store.

I bought OSRAM LED superstar PAR16 35 25 This is a 40 vac 4.

35 W GU10 halogen lamp 5 W replacement.

It has a narrow beam angle of 25 degrees.

If you search the internet for example 12V or a single LED instead of 3 LED arrays, there may be a better unit to start.

I love this Osram as it is close to the water tight and takes apart with screws and looks like a part. (

Unfortunately, I did not take any photos of the spotlight that were not modified

But you can imagine that in the photo below, the GU10 terminal is in the position of the switch and the lead exit, in other words, it does not change on the outside. Unfortunately -

I didn\'t start taking pictures (

Because my daughter lost her camera charger! ).

These photos are usually taken afterwards, using an unreliable BlackBerry.

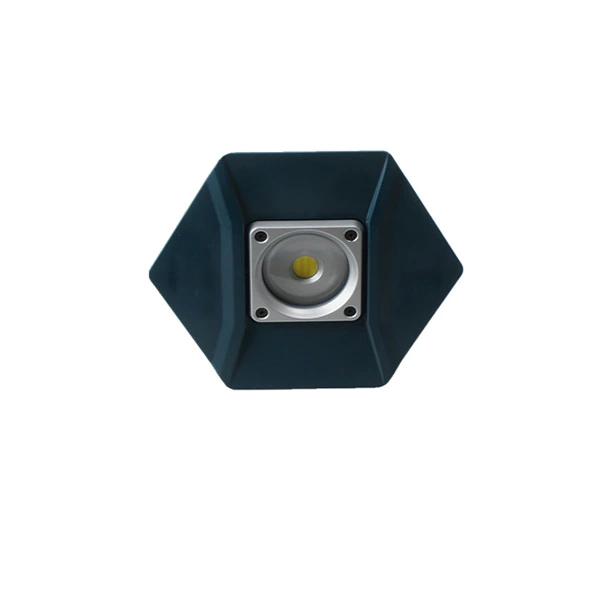

The lights are made.

Up to 7 parts: o lens clip ring-

Aluminiumo lens

Plastic LED board-

Radiator/lampshade-

Aluminiumo electronic capsule

Plastic Electronics-

PCBo insulation cap-

By simply unscrewing the 3 small Allen key screws, the lens clamp ring and lens can be removed.

This will show the LED board with 3 LEDs and some electronic components and terminals.

Remove the 3 cross screws on the LED board, release the board, radiator and electronic capsule.

You will need to scrape off the spots of silicone rubber and unwrap the welding of the plate wire to completely release these 3 parts.

Overall it\'s a radiator and you need a decent soldering iron to get enough heat.

Also be careful that there are radiator welding compounds on the back of the plate.

Since it is usually toxic, I carefully wipe it off.

You need to be very careful about those rough surfaces.

I put a piece of lint-free cloth on them to make sure they don\'t pick --Fingerprints.

The electronic capsule and lid look like a separate unit, but you can remove it from the lid.

At the other end I heated the GU10 terminals until they melted the plastic and then pushed it away.

If you want to keep the terminals, you need to drill out the clamping pin holes.

Once the lid is removed and the terminals are pushed, the electronic device will fall off.

There should be 7 parts and 6 screws on your bench right now!

A few hours later, I studied electronics and LED boards, walked around with a multimeter, while temporarily powering the device from the power supply, and I had some knowledge of how the device works.

The electronics produces a variable AC power supply of about 14 VAC and 350 mA.

To the LED board.

This is the fault of the final output transformer.

There are many electronic devices that drive the transformer, presumably ensuring that the final result is a constant current of the led.

There is a rectifier diode, a pair of capacitors and a resistor on the LED board (

And led in series).

This gives a half wave rectifier and a charging pump.

This means that it is difficult to determine the actual current and duty cycle of the LEDs without using osillisoft for monitoring if it is not understood to develop the soldering of the LEDs.

The only thing that needs to continue is a reasonable constant 9.

6Vdc of 3 LEDs.

Combined with quotation 4.

5 W, about 450 mA.

As the led may pulse (

So the heat is reduced)

I plan to apply for a DC power supply of about 350 mA.

At this point, I stole a useful circuit from Dan.

See MosFET used, drain transistor, collector resistor (47Kohms)

And the choice of current sensing resistance (1. 5ohms, 4. 1ohms).

I bought everything from the local store.

These offer 370 mA and 180 mA via led to provide high power mode and battery saving mode.

I found an old cordless drill with 14 for the battery.

Rechargeable battery for 4 V.

It barely gives 12 V when it is woven, but it is still 1 V.

5 Ah, this is 4 hours of bicycle lighting time with high brightness.

I might end up buying a smaller LIon battery.

The key to my plan is to install all of these electronic and DPDT switches within the existing housing.

So I bought a submarine.

Miniture 3 position switch with waterproof cover.

After drilling out the GU10 terminal hole at the bottom of the electronic capsule to get the switch and battery leads, I was able to determine the space for the electronic product, which would be a tight fit.

I made a chamfer on the base to allow the switch to point up slightly instead of straight back.

This provides more space for electronics and makes it easier to operate switches when riding bicycles.

I basically build it by welding the transistor leads as close to each other as possible, then welding the resistors and connecting some leads as closely as possible between the switch and the transistor assembly.

I insulated the wires as much as possible with some stripped wire insulation.

The Circuit of the LED board also needs to be modified.

I removed the diode and resistor.

I replaced the diode with a tin wire.

I think they might give some switch spike suppression but I didn\'t remove the capacitor.

After a lot of trial fitting and very short lead welding, I was able to slide the electronics into the capsule, poke the switch Rod and battery lead through the terminal hole, change the electronic cap, poke two fine lines through the existing cap holes, ready to weld to the plate when reassembling.

The first thing to note is that all the parts are typed in a specific direction and only fit together.

In addition to drilling the terminal hole a little bigger and chamfer the base, the only other change I made to the outside was to place some silver tape around half of the lens.

This will prevent light from leaking from the side of the lens (

Through radiator blades)

Distract the rider

I let the lower half of the lens leak light on the front wheel.

Because this can only help improve visibility.

If you want the hole unit to be waterproof, now is the time to add a fine silicon film to the bottom of the radiator (

Matching place with electronic capsule)

To the lower edge of the lens (

Matching place with radiator).

There is a slight cut on the edge of the lens, which seems to be a \"breathing\" point.

This also requires recording or sealing.

The switch I bought has a water cap and the size of the battery cable hole is for tight fit strain elimination, with a little bit of silicon, completely waterproof.

The only tricky part of reassembly is to weld the LED board terminals to the flying leads of the electronics.

I did this before tightening the screws to the radiator to make sure the iron is not soaked into the whole unit.

If you feel that you may have come into contact with the LED surfaces, you need to polish them carefully with lint-free cloth.

To connect to the lead from the battery, I used the standard online (laptop)

DC power connector.

I just simply modified and the existing LED backlight bracket-

Buy 2 to 3 pounds from the supermarket (

With a range of accessories).

It fits well with the cable tie.

But I might get something more neat.

The first impression of use is-

Very bright.

My main concern is the blinding driver, I will make it drop sharply and I will only use high power mode if no one comes in another direction.

Let me know if you want more information and I will try to get some decent photos and upload my scrawled chart.

Nowadays, it is very common for us to utilise in portable led work light suppliers. And the quality of is decisive to production efficiency.

As a result, consumers will reward Taiyi Electronic with leadership sales, profit, and value creation, allowing our customers in which we live and work to prosper.

But we do think that reckoning with supply chains of led work light supplier is a really important step. Even super simple switches in material, or sourcing, or shipping, or worker benefits seems like good place to start.

In my opinion, a good home headheld spotlight will be a very cheap front light for a bike.

The perfect Osram headheld spotlight-

In my local DIY shop

So I went.

I am very satisfied with the results.

I found out that I spent about £ 20 doing a bike light and retail £ 200 from the bike store.

I bought OSRAM LED superstar PAR16 35 25 This is a 40 vac 4.

35 W GU10 halogen lamp 5 W replacement.

It has a narrow beam angle of 25 degrees.

If you search the internet for example 12V or a single LED instead of 3 LED arrays, there may be a better unit to start.

I love this Osram as it is close to the water tight and takes apart with screws and looks like a part. (

Unfortunately, I did not take any photos of the spotlight that were not modified

But you can imagine that in the photo below, the GU10 terminal is in the position of the switch and the lead exit, in other words, it does not change on the outside. Unfortunately -

I didn\'t start taking pictures (

Because my daughter lost her camera charger! ).

These photos are usually taken afterwards, using an unreliable BlackBerry.

The lights are made.

Up to 7 parts: o lens clip ring-

Aluminiumo lens

Plastic LED board-

Radiator/lampshade-

Aluminiumo electronic capsule

Plastic Electronics-

PCBo insulation cap-

By simply unscrewing the 3 small Allen key screws, the lens clamp ring and lens can be removed.

This will show the LED board with 3 LEDs and some electronic components and terminals.

Remove the 3 cross screws on the LED board, release the board, radiator and electronic capsule.

You will need to scrape off the spots of silicone rubber and unwrap the welding of the plate wire to completely release these 3 parts.

Overall it\'s a radiator and you need a decent soldering iron to get enough heat.

Also be careful that there are radiator welding compounds on the back of the plate.

Since it is usually toxic, I carefully wipe it off.

You need to be very careful about those rough surfaces.

I put a piece of lint-free cloth on them to make sure they don\'t pick --Fingerprints.

The electronic capsule and lid look like a separate unit, but you can remove it from the lid.

At the other end I heated the GU10 terminals until they melted the plastic and then pushed it away.

If you want to keep the terminals, you need to drill out the clamping pin holes.

Once the lid is removed and the terminals are pushed, the electronic device will fall off.

There should be 7 parts and 6 screws on your bench right now!

A few hours later, I studied electronics and LED boards, walked around with a multimeter, while temporarily powering the device from the power supply, and I had some knowledge of how the device works.

The electronics produces a variable AC power supply of about 14 VAC and 350 mA.

To the LED board.

This is the fault of the final output transformer.

There are many electronic devices that drive the transformer, presumably ensuring that the final result is a constant current of the led.

There is a rectifier diode, a pair of capacitors and a resistor on the LED board (

And led in series).

This gives a half wave rectifier and a charging pump.

This means that it is difficult to determine the actual current and duty cycle of the LEDs without using osillisoft for monitoring if it is not understood to develop the soldering of the LEDs.

The only thing that needs to continue is a reasonable constant 9.

6Vdc of 3 LEDs.

Combined with quotation 4.

5 W, about 450 mA.

As the led may pulse (

So the heat is reduced)

I plan to apply for a DC power supply of about 350 mA.

At this point, I stole a useful circuit from Dan.

See MosFET used, drain transistor, collector resistor (47Kohms)

And the choice of current sensing resistance (1. 5ohms, 4. 1ohms).

I bought everything from the local store.

These offer 370 mA and 180 mA via led to provide high power mode and battery saving mode.

I found an old cordless drill with 14 for the battery.

Rechargeable battery for 4 V.

It barely gives 12 V when it is woven, but it is still 1 V.

5 Ah, this is 4 hours of bicycle lighting time with high brightness.

I might end up buying a smaller LIon battery.

The key to my plan is to install all of these electronic and DPDT switches within the existing housing.

So I bought a submarine.

Miniture 3 position switch with waterproof cover.

After drilling out the GU10 terminal hole at the bottom of the electronic capsule to get the switch and battery leads, I was able to determine the space for the electronic product, which would be a tight fit.

I made a chamfer on the base to allow the switch to point up slightly instead of straight back.

This provides more space for electronics and makes it easier to operate switches when riding bicycles.

I basically build it by welding the transistor leads as close to each other as possible, then welding the resistors and connecting some leads as closely as possible between the switch and the transistor assembly.

I insulated the wires as much as possible with some stripped wire insulation.

The Circuit of the LED board also needs to be modified.

I removed the diode and resistor.

I replaced the diode with a tin wire.

I think they might give some switch spike suppression but I didn\'t remove the capacitor.

After a lot of trial fitting and very short lead welding, I was able to slide the electronics into the capsule, poke the switch Rod and battery lead through the terminal hole, change the electronic cap, poke two fine lines through the existing cap holes, ready to weld to the plate when reassembling.

The first thing to note is that all the parts are typed in a specific direction and only fit together.

In addition to drilling the terminal hole a little bigger and chamfer the base, the only other change I made to the outside was to place some silver tape around half of the lens.

This will prevent light from leaking from the side of the lens (

Through radiator blades)

Distract the rider

I let the lower half of the lens leak light on the front wheel.

Because this can only help improve visibility.

If you want the hole unit to be waterproof, now is the time to add a fine silicon film to the bottom of the radiator (

Matching place with electronic capsule)

To the lower edge of the lens (

Matching place with radiator).

There is a slight cut on the edge of the lens, which seems to be a \"breathing\" point.

This also requires recording or sealing.

The switch I bought has a water cap and the size of the battery cable hole is for tight fit strain elimination, with a little bit of silicon, completely waterproof.

The only tricky part of reassembly is to weld the LED board terminals to the flying leads of the electronics.

I did this before tightening the screws to the radiator to make sure the iron is not soaked into the whole unit.

If you feel that you may have come into contact with the LED surfaces, you need to polish them carefully with lint-free cloth.

To connect to the lead from the battery, I used the standard online (laptop)

DC power connector.

I just simply modified and the existing LED backlight bracket-

Buy 2 to 3 pounds from the supermarket (

With a range of accessories).

It fits well with the cable tie.

But I might get something more neat.

The first impression of use is-

Very bright.

My main concern is the blinding driver, I will make it drop sharply and I will only use high power mode if no one comes in another direction.

Let me know if you want more information and I will try to get some decent photos and upload my scrawled chart.

Nowadays, it is very common for us to utilise in portable led work light suppliers. And the quality of is decisive to production efficiency.

As a result, consumers will reward Taiyi Electronic with leadership sales, profit, and value creation, allowing our customers in which we live and work to prosper.

But we do think that reckoning with supply chains of led work light supplier is a really important step. Even super simple switches in material, or sourcing, or shipping, or worker benefits seems like good place to start.